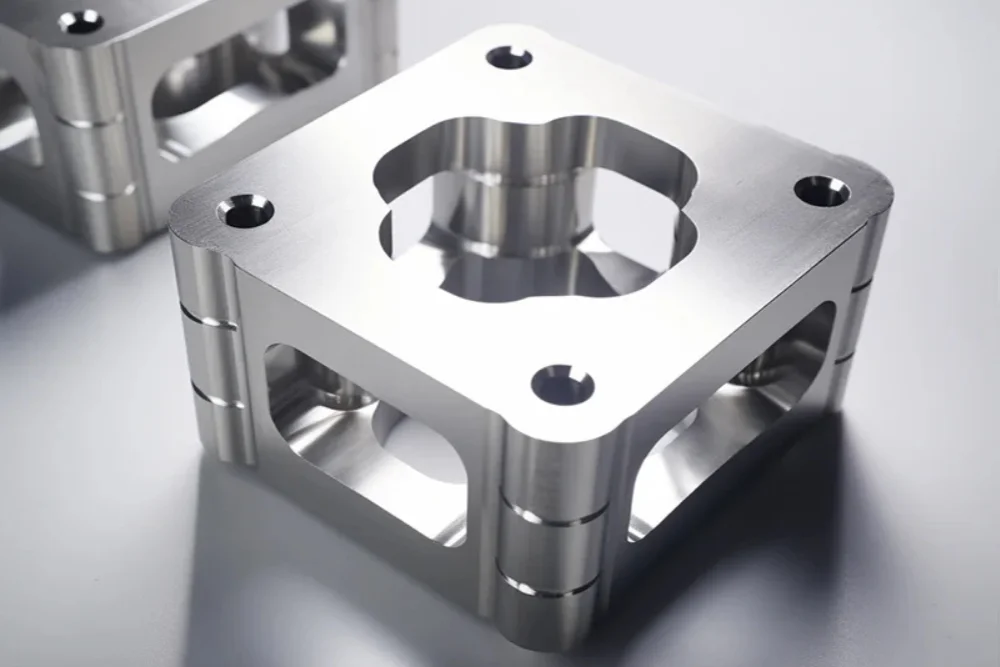

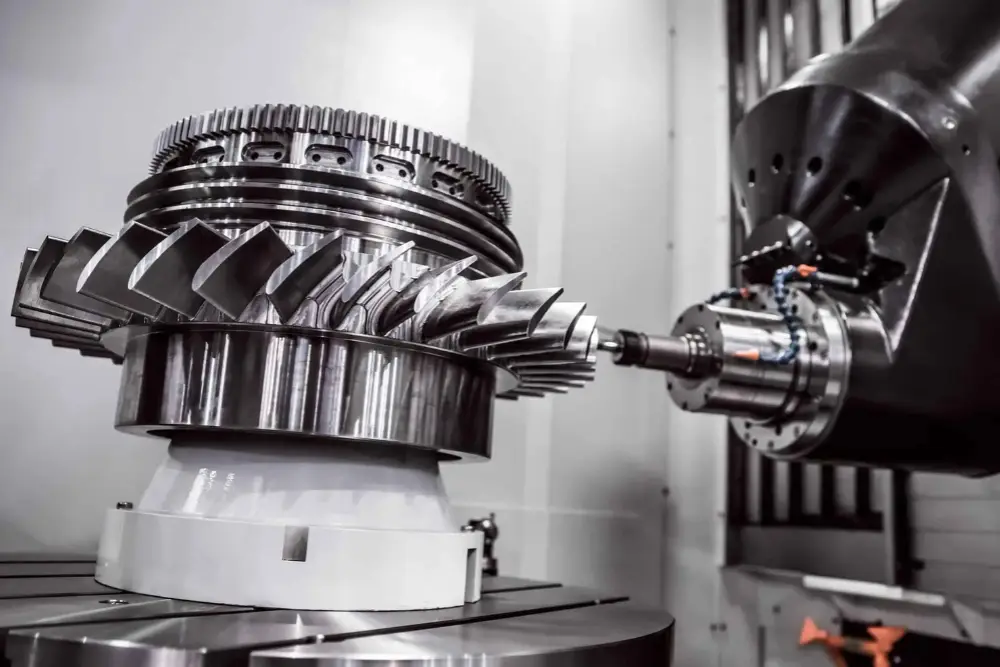

We deliver high tolerance machined components with precise dimensions, ensuring seamless integration and optimal performance in critical applications.

Product Overview

Accuracy for demanding applications

Our high tolerance machined components are crafted with meticulous precision to meet the strictest dimensional requirements. Using advanced CNC machining technology, we ensure every part fits perfectly, minimizing assembly issues and enhancing overall product reliability.

Ideal for industries where precision is paramount, our components support applications ranging from aerospace to automotive, offering superior quality and consistent performance.

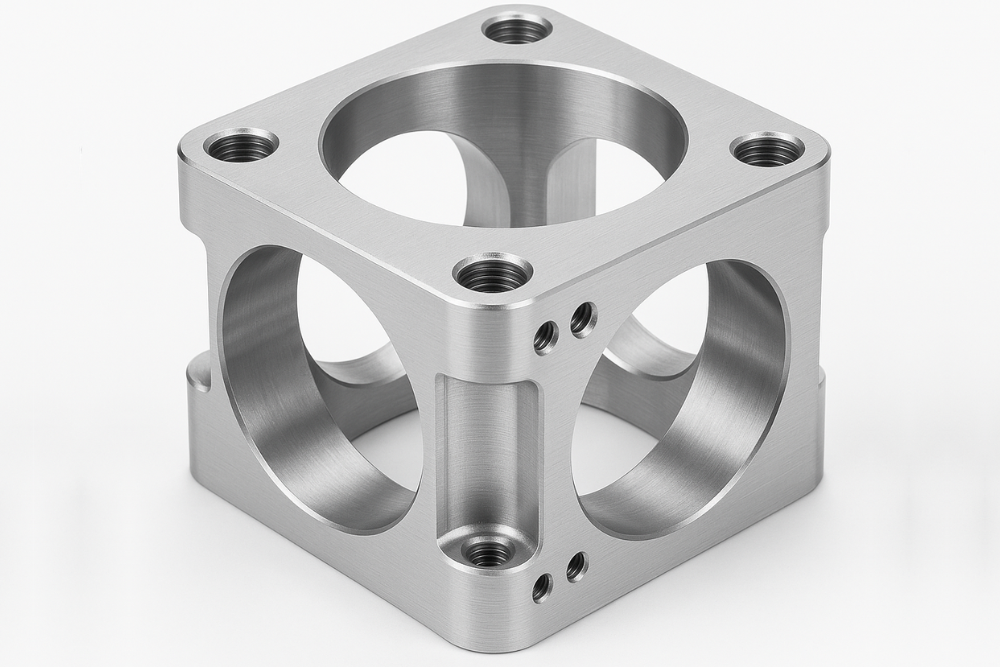

Our machining capabilities encompass advanced multi-axis CNC milling, turning, grinding, and EDM operations, enabling the production of intricate components with tight tolerances up to ±5 microns. We work across a diverse range of materials—including stainless steel, titanium, aluminum, and high-performance super alloys—delivering precision-engineered solutions tailored to demanding application requirements in sectors like aerospace, automotive, and industrial engineering.

Each component we produce undergoes rigorous quality control, including CMM inspection, surface finish testing, and dimensional verification to ensure consistency and compliance. Whether it’s a one-off prototype or a large-scale production run, our machining services guarantee components that meet global quality benchmarks, offering exceptional reliability, durability, and compatibility with your existing systems and assemblies.

Core Advantages

Essential qualities driving performance

Precision Engineering

Manufactured to exact tolerances for flawless performance in critical applications.

Advanced Technology

CNC machining with high-end tools ensures repeatability and ultra-fine accuracy.

Consistent Quality

Each component meets stringent quality checks for durability and dimensional accuracy.

Certified Excellence

Certifications & Quality Assurance

Certified Excellence

Certifications & Quality Assurance

Why Choose Us?

Trusted Engineering Partner

Our Products

Precision Products Proven Performance