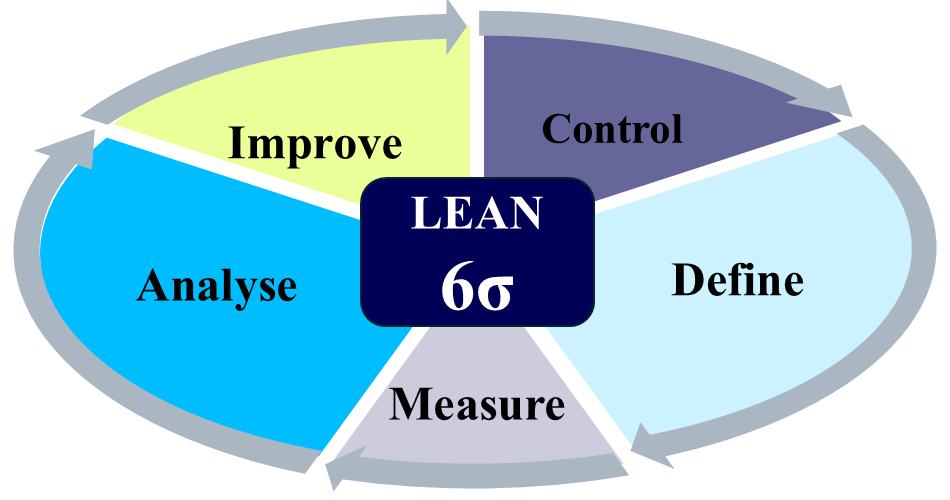

Lean and Six Sigma

Optimize Quality, Eliminate Waste

Enhance process efficiency, minimize variation, and boost performance using Lean and Six Sigma methodologies for continuous business improvement.

Process Excellence

Driving Continuous Process Improvement

Lean and Six Sigma are proven methodologies focused on improving efficiency, reducing waste, and delivering high-quality results. By identifying bottlenecks and eliminating process variation, these practices help businesses streamline operations and enhance customer satisfaction.

Our approach combines data-driven decision-making with hands-on strategies tailored to your business needs. Whether in manufacturing, service, or logistics, we empower teams to build a culture of continuous improvement and achieve measurable, long-term success.

Product Innovation

New Product Development & Engineering Consultation

We provide comprehensive support throughout the entire product development lifecycle from initial concept and design to prototyping, testing, and production planning. Our engineering experts work closely with you to transform innovative ideas into practical, market-ready products that meet quality, cost, and timeline goals. Whether it’s refining designs, selecting materials, or navigating patent documentation, we deliver tailored solutions that accelerate your product’s success.

Our Process

How We Bring Your Ideas to Life

Discovery & Ideation

We analyze your concept, explore potential solutions, and assess feasibility to ensure a strong, strategic starting point.

Concept Design

Our team defines your product’s architecture, core features, and design intent through concept modeling and visualization.

Engineering & Prototyping

We create detailed CAD models and functional prototypes to test, iterate, and refine before moving to production.

What We Offer

Enhancing Efficiency and Quality

We provide tailored Lean and Six Sigma solutions to optimize processes, reduce waste, and ensure consistent, high-quality outcomes across operations.

Process Optimization

Quality Management

Performance Improvement

Industries We Serve

Precision Solutions for Leading Sectors

We support aerospace, automotive, medical, energy, and industrial sectors with reliable, high-performance engineering solutions.

Why Choose Us?

Trusted Engineering Partner

Get a Quote

Request a personalized quote for your project. Simply share your requirements, and our team will provide a detailed, competitive proposal tailored to your needs.

Featured

Most popular questions.

Find answers to common inquiries about our products, services, and processes. If you need further assistance, feel free to contact us.

We serve a wide range of industries including automotive, aerospace, oil and gas, power generation, construction, manufacturing, and more. Our solutions are tailored to meet the specific needs of each industry, ensuring high-quality, cost-effective, and reliable manufacturing processes.

We specialize in a variety of products including castings, CNC machined components, forged parts, custom tooling, and high-precision components. We offer solutions for valves, rotating equipment parts, automotive engine components, turbine blades, and much more.

We follow rigorous quality control processes, including CMM inspection and third-party certifications (such as AS9100D and ISO9001). Our team ensures that all products meet the highest standards of performance, durability, and precision.

The lead time for custom orders depends on the complexity and size of the project. Once we understand your requirements, we provide a detailed timeline. We aim to deliver all projects on time while maintaining the highest standards of quality.